|

Common pinned condenser

As a result of the smaller hole opening (180° cross each other), it increases the uneven distribution of gas flow resistance, easy to produce bias.Not suitable for use in a vacuum.

Very thick, slow condensed water flow,low heat exchange efficiency.

General use of 20mm or more washers, expansion of shrinkage, deformation, low pressure, especially when used in high vacuum, and often leak. |

|

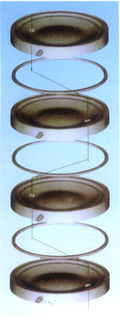

Porous pinned condenser

After research, improvement and testing according to the disadvantages of common pinned condenser, now we have designed and produced new pinned condenser.The device can be used for high vacuum distillation apparatus (vacuum up to 130Pa), improved pressure drop, leaks and other issues.

The use of tin design, reducing the condensation thickness to improve the cooling water flow rate, condenser with the same general area compared to the heat transfer efficiency increased by 50% or more, and difficult to scale.

Using a 10mm gasket, expansion and contraction of small, high pressure.

Nozzle and the size can be changed according to user needs. |